When an aircraft descends through the final metres of an approach in near-zero visibility, the pilot’s first visual contact with the runway often comes from a narrow band of light bars embedded in the pavement just beyond the threshold. Those are the touchdown zone lights, commonly known as TDZ lights. They may not get as much attention as approach or centreline systems, but in low-visibility operations they are absolutely essential. Without them, a runway simply cannot be certified for CAT II or CAT III approaches.

In this article we will walk through what TDZ lights are, how ICAO and other standards define their layout, why they become mandatory at higher approach categories, and what airport operators need to keep in mind when choosing, installing, and maintaining them.

1. What Are Touchdown Zone Lights?

In simple terms, TDZ lights are flush-mounted (in-pavement) light bars that cover the first 900 metres of the runway beyond the threshold. That 900-metre stretch is the designated touchdown zone: the area where the aircraft is expected to make initial contact with the surface.

What makes TDZ lights easy to distinguish from other runway lighting is their arrangement. Rather than running along the centerline or the edges, they are laid out as transverse bars, short rows of lights placed perpendicular to the centerline. When viewed from the cockpit on approach, this creates a distinctive «ladder» pattern that gives the pilot a strong sense of where the runway surface starts and how high they are above it.

This matters because, at the very end of a precision approach, the crew needs to judge height, alignment, and descent rate almost simultaneously. TDZ lights give them that reference.

Key Functions of TDZ Lights

So what exactly do TDZ lights do during a landing? A few things.

They give pilots positive identification of the touchdown zone. When visibility is down to a few hundred metres (or less), knowing you are over the actual runway surface, and not still over the approach area, is not a small detail. It can be the difference between a safe landing and a go-around.

They also help with depth perception during the flare. The flare is that brief transition where the pilot pulls back slightly to reduce the descent rate just before the wheels touch. Good depth cues from the TDZ lights make this manoeuvre much more precise.

On top of that, TDZ lights act as a visual bridge between the approach lighting system and the runway centerline and edge lights. The approach lights guide the aircraft down to the threshold; the TDZ lights pick up from there and confirm the pilot is over the landing surface. Without that bridge, there would be a visual gap at the worst possible moment.

Finally, they are a core requirement for CAT II and CAT III operations, where decision heights can be as low as 15 metres or, in the case of CAT IIIC, zero.

To see how TDZ fits within a full runway lighting configuration, see below how our TDZZ-08-LED lights bright in Konrad Adenauer Airport (Cologne – Germany):

2. ICAO Standards for Touchdown Zone Lighting

The specifications for TDZ lights come primarily from ICAO Annex 14, Volume I (Aerodrome Design and Operations). This is the international baseline that bodies like EASA in Europe and the FAA in the United States build upon, sometimes with local additions.

2.1 When Are TDZ Lights Required?

ICAO Annex 14 is quite clear on this point: touchdown zone lights shall be provided on precision approach runways of Category II and Category III. For Category I runways, they are recommended but not mandatory.

In practical terms, if your airport wants to operate (or get certified for) CAT II or CAT III approaches, a TDZ lighting system is not optional. It is a required part of the airfield ground lighting (AGL) infrastructure.

2.2 Layout and Configuration

ICAO defines a specific geometry for the TDZ system. Here is how it works in practice.

The system covers the first 900 m of runway from the threshold. Light bars are arranged in pairs, one on each side of the centreline. Each bar has at least three in-pavement fittings aligned across the runway. The spacing between consecutive pairs is 30 m (though some configurations use 60 m, depending on local rules and the approach category). The bars sit roughly 9 to 11 m from the centreline, depending on runway width. And all the lights emit unidirectional white light, visible only to aircraft on approach.

Seen from the cockpit, this layout produces a clear «barrette» pattern. Even in very poor visibility, the pattern is strong enough to give the crew reliable surface-level guidance.

2.3 Photometric Requirements

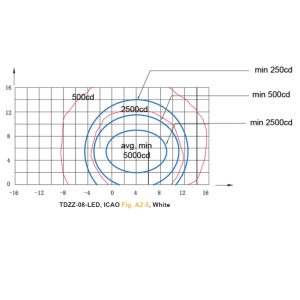

Getting the physical layout right is only half the job. The lights themselves also need to meet strict photometric specifications from ICAO Annex 14 and the Aerodrome Design Manual (Doc 9157).

This means the fittings need to produce enough candela output to be visible at the decision height for the relevant approach category. The beam spread (both vertical and horizontal) must be tightly controlled so the light reaches the pilot’s eyes at the right approach angle without creating glare. And the colour must be a specific aviation white, within the chromaticity coordinates that ICAO defines.

Modern LED fittings like the TDZZ-08-LED from the Airsafe range are designed from the ground up to meet all of these photometric criteria, while also bringing the efficiency and longevity benefits that come with LED technology.

3. Why Touchdown Zone Lights Are Critical for CAT II and CAT III Operations

If TDZ lights are only «recommended» for CAT I, why do they become mandatory at CAT II and above? The answer lies in what changes as you move up the approach categories.

3.1 Understanding Approach Categories

ICAO classifies precision approaches based on two things: the Decision Height (DH), which is the lowest altitude at which the pilot must see enough of the runway environment to continue, and the Runway Visual Range (RVR), which is how far down the runway the pilot can see.

At CAT I, the DH is no lower than 60 m (200 ft) and the RVR is at least 550 m. That still gives the crew a reasonable amount of time and visual reference to assess the landing.

At CAT II, the DH drops to between 30 and 60 m, with an RVR of at least 300 m. Things get tighter.

CAT IIIA pushes the DH below 30 m, with an RVR of at least 175 m. CAT IIIB can have a DH below 15 m, or no DH at all, with RVR as low as 50 m. And CAT IIIC represents full zero-visibility operations: no DH, no RVR minimum.

The lower the decision height, the less time the crew has to pick up visual references. At CAT II and III, the TDZ lights are often the first (and sometimes the only) surface-level cue available at decision height.

3.2 The Role of Touchdown Zone Lights in Low-Visibility Operations (LVO)

During a CAT II or CAT III approach, pilots typically pick up visual cues in a specific sequence. Higher up, the approach lighting system gives the first visual guidance, helping the crew identify the runway environment from a distance. Then, as the aircraft descends through the decision height, the Touchdown Zone Lights become visible, confirming that the aircraft is now over the actual runway surface. From that point on, the centerline and edge lights take over and provide lateral guidance through the flare and rollout.

If the TDZ lights were not there, there would be a gap between the approach lights (which stop at the threshold) and the centreline and edge lights. In conditions where the RVR is 300 m or less, that gap could leave the pilot without any positive surface identification at the most critical moment of the approach. That is exactly why ICAO requires TDZ lighting for these categories: it fills that gap and ensures a continuous visual transition from approach to runway.

3.3 Regulatory and Certification Implications

Beyond the safety argument, there is a very practical commercial side to this. If a runway does not have a compliant TDZ lighting system, it cannot be certified for CAT II or CAT III operations. Full stop.

That means airlines cannot dispatch flights to the airport under Low-Visibility Procedures, which leads to diversions and cancellations whenever fog, low cloud, or heavy rain rolls in. The airport also loses ground against nearby competitors that do hold CAT II/III certification. For airports in regions where poor visibility is common (think northern Europe, coastal locations, or highland airports), the revenue impact of not having CAT II/III capability can be very significant.

So a well-designed TDZ system is not just about regulatory compliance. It is about keeping the airport open when the weather tries to shut it down.

4. TDZ Light Technology: Halogen vs LED

For decades, Touchdown Zone lights (along with most other AGL fittings) relied on halogen or incandescent lamp technology. Halogen has a long track record and is well understood, but it comes with some well-known operational headaches: high power consumption, frequent lamp changes, progressive colour shift as lamps age, and heat buildup inside the fitting.

4.1 The Shift to LED

Over the past several years, the airfield lighting industry has been moving steadily towards LED, and TDZ systems are following the same path. The reasons are hard to argue with.

LED fittings typically use 40 to 60% less power than their halogen equivalents for the same light output. That reduces the load on constant current regulators (CCRs) and brings down electricity costs noticeably across a full runway installation.

The operational life is also in a different league. LED sources can run for over 50,000 hours, compared to 1,000 to 2,000 hours for a halogen lamp. In practice, that means far fewer maintenance visits on the runway surface, which in turn means fewer closures and less disruption to flight operations.

Colour stability is another area where LED pulls ahead. Halogen lamps gradually shift towards yellow as they age, which can affect photometric compliance. LED maintains consistent chromaticity throughout its life. And there is no warm-up time: LED reaches full output the instant it is switched on.

AES Airport Solutions supplies the TDZZ-08-LED, an in-pavement LED touchdown zone light from the Airsafe range. It is built to meet ICAO, FAA, and EASA photometric requirements while delivering all the efficiency and reliability benefits of modern LED technology.

4.2 Retrofit Considerations

A common question we hear from airport operators is whether they need to rip out their entire existing installation to go LED. In most cases, the answer is no.

Many airports are upgrading their halogen TDZ fittings to LED while keeping the existing infrastructure in place. The main things to evaluate in a retrofit are: whether the new LED fittings are compatible with the existing series circuits and CCRs (most modern LED fittings work on standard 6.6A circuits), whether the existing in-pavement bases and mounting hardware can be reused (have a look at our mounting accessories for compatible options), whether photometric re-certification is needed to confirm compliance with the required approach category, and whether it makes sense to also upgrade the lighting control system to add remote monitoring and individual lamp status reporting.

5. Installation and Maintenance Best Practices

5.1 Installation Considerations

Getting TDZ lights installed properly matters more than you might think. These are in-pavement fittings on an active runway, so the margin for error is small.

Every fitting must sit perfectly flush with the runway surface. Even a slight protrusion creates a Foreign Object Debris (FOD) risk and could damage aircraft tyres. Alignment is equally important: if a fitting is off by even a few degrees, the beam may not reach the pilot’s eyes at the correct approach angle, which defeats the purpose of having the light there in the first place.

Drainage around each fitting also needs careful attention. Water that gets trapped around or under a fitting can lead to ice formation in cold weather, potentially lifting the unit out of the pavement or blocking the optical surface. And, of course, all Touchdown Zone Lights fittings and their associated hardware must be frangible. That means they are designed to break away cleanly on impact rather than damaging the aircraft. This is a core airfield safety requirement, and to find more detail of how a great quality product, like the Zero Water series manufactured by Airsafe, can avoid such problems, please read our article New Airsafe Z ZSeries.

5.2 Maintenance and Monitoring

ICAO and national regulators set minimum serviceability levels for TDZ lighting. The typical threshold is that at least 90% of fittings must be operational for the runway to keep its approach category. Drop below that, and the airport may have to temporarily downgrade the runway.

A solid maintenance programme covers regular photometric checks (to make sure intensity and beam alignment are still within spec), lamp or LED module replacement (much less frequent with LED), cleaning of the optical surfaces to remove rubber deposits, oil, and other debris, and ongoing electrical monitoring through the CCR system.

Modern AGL control systems make this easier than it used to be. They can monitor each fitting individually and in real time, flagging failures as they happen so the maintenance team can schedule repairs before the serviceability threshold is breached.

6. Conclusion

Touchdown zone lights may not be the most talked-about element of an airfield lighting system, but they are one of the most important. They fill a critical visual gap between the approach lights and the runway surface, giving pilots the reference they need to land safely in the toughest visibility conditions.

ICAO mandates them for CAT II and CAT III runways, and for good reason. The shift from halogen to LED is making these systems more efficient, longer-lasting, and easier to maintain, without compromising on photometric performance.

For airport operators looking to achieve CAT II/III certification, or to modernise an existing installation, a well-specified LED TDZ system is one of the smartest investments on the table.

AES Airport Solutions, as the official European distributor for Airsafe airfield ground lighting equipment, offers a complete range of runway lighting products, including the TDZZ-08-LED in-pavement touchdown zone light, backed by technical support, after-sales service, and proven references across major European airports.

Want to talk about your TDZ lighting project? Get in touch with our team and we will be happy to help.